PHR Chain Clamp Rockwell Hardness Tester which can test the hardness of cylindrical workpieces such as pipes, shafts, rollers accurately on-site. The test principle and accuracy comply to standard ISO 6508 and ASTM E110. Tested by National Institute of Metrology with tolorance <1.5HRC, equivalent to bench hardness tester. So this kind of metal hardness tester is usually used for manufacturing inspection and acceptance inspection to replace Leeb hardness tester with lower accuracy.

Features of PHR-64 Chain Clamp Rockwell Hardness Tester

-

-

1 On-site Tesing Testing the hardness of large pipes and shafts accurately on-site.

-

-

2 Anvils Testing various dimensions and shapes workpiece by using different anvils.

-

-

3 Application Chain fastened around the workpiece before the force is applied.

-

-

4 Relevant Standards Comply to standard ISO 6508 and ASTM E18, E110

-

-

5 Hardness Block Traceable standard hardness block

-

-

6 Indenter Indenter inspected by standard Rockwell hardness tester

Technical Parameters of PHR-64 Chain Clamp Rockwell Hardness Tester

|

Initial Test Force: 10kgf

Total Test Force: 60kgf, 100kgf, 150kgf

Force Applying Method: By Screw

Indenter: 120°diamond cone

Ф1.588mm carbide ball

Accuracy: Meets the requirements of ISO6508,ASTM E18

Resolution: 0.5HR

Testing Range: HRA, HRB, HRC, etc.15 scales.

Application: All metals including iron, steel, copper, aluminium, etc.

|

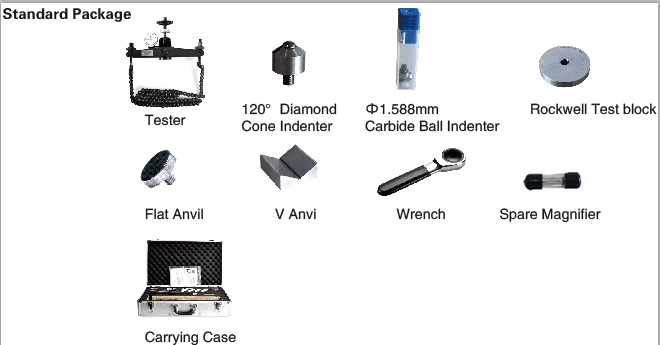

Package of PHR-64 Chain Clamp Rockwell Hardness Tester