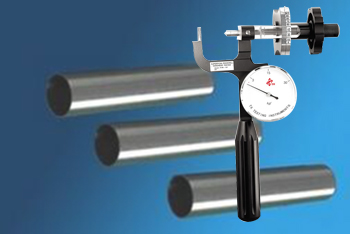

PHR-1ST portable superficial Rockwell hardness testers comply with the basic designing principles of Rockwell hardness testing in accordance with international standard ISO6508, American Standard ASTM E18 and ASTM E110. The hardness values can be read directly from the superficial Rockwell hardness testers after rapid and accurate operations. It can be considered as a non-destructive testing with very small indentations. This kind of testers can be used at site to test the finished or semi-finished work pieces piece by piece in batches. Superficial Rockwell hardness testers are mostly applied in the metal-processing enterprises.

Features of PHR-1ST Superficial Rockwell Hardness Tester

-

-

1 High Accuracy comply to standard ISO6508 and ASTM E18, E110

-

-

2 Convenient to Use Used on the desk as well as on site

-

-

3 Wide Test Range Test thin plate, shaft, small ball and so on

-

-

4 Anvil Test tin plate and cold-rolled sheet with diamond raised spot anvi

-

-

5 Indentation Small indentation and NDT testing on finished workpiece

-

-

6 Test Block Traceable standard hardness block

Technical Parameters of PHR-1ST Superficial Rockwell Hardness Tester

|

Initial Test Force: 3kgf

Total Test Force: 15kgf

Indenter: Ф1.588mm carbide ball

Accuracy: Meets the requirements of ISO6508,ASTM E18

Resolution: 0.5HR

Testing Range: HRN, HRT,HRW, HRX, HRY, etc. 15 scales.

Application: All metals including iron, steel, copper,aluminium,zinc, lead, tin, carburized steel, nitrided steel etc.

|

Package of PHR-1ST Superficial Rockwell Hardness Tester