Fix Rockwell test head to the surface of iron and steel parts to test the hardness by applying magnetic force. Follow Rockwell hardness test method completely and the test condition complies with standard of ISO 6508 and ASTM E 18.

The magnetic Rockwell hardness tester is mainly applied in on-site quick test body hardness of steel parts.

Test hardness of steel plate, pipe, axis, mould, huge forgings and huge and medium-size heat treatment parts if surface available.

Test hardness of weld joint in boiler, pressure vessels, and pressure pipes.

Replace low accurate and reliable Leeb hardness testers.

PHR-100 Magnetic Rockwell Hardness Tester Operation Video

Features of PHR-100 Magnetic Rockwell Hardness Tester

-

-

1 Convenient to Use Attach to one side of part to test, no need to move it.

-

-

2 NDT Testing Quick, convenient, no damage test.

-

-

3 Reading Scale Similar reading system as micrometers, easy to read, and good repeatability.

-

-

4 High Accuracy Rather high accuracy, complying with ISO6508 and ASTM E18.

Technical Parameters of PHR-100 Magnetic Rockwell Hardness Tester

|

Initial Test Force for Rockwell: 10kgf

Total Test Force: 60kgf, 100kgf, 150kgf

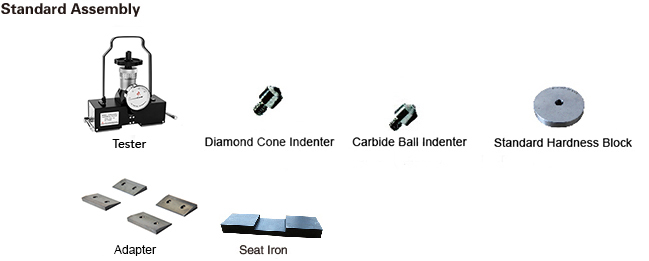

Test head: 120°diamond indenter, 1.588mm carbide ball indenter

Indication Error: Comply with ISO 6508 and ASTM E 18

Indication Error: Comply with ISO 6508 and ASTM E 18

Testing Resolution: 0.5 HR

Weight: 4.7 kg

Surface: Flat : Area ≥ 180 mm x 60 mm Thickness : ≥ 5 mm

Cylinder: Diameter ≥ 60 mm Length ≥ 200 mm, Thickness ≥ 8 mm |

Relevant standards of PHR-100 Magnetic Rockwell Hardness Tester

ASTM Standards

ASTM E18-15 Standard Test Methods for Rockwell Hardness of Metallic Materials

International Standards

Metallic materials —— Rockwell hardness test Part 2: Verification and calibration of testing machines and indenters

Package of PHR-100 Magnetic Rockwell Hardness Tester